The Armory Life Interviews: Black Hills’ Jeff and Kristi Hoffman

While Black Hills Ammunition today is ubiquitous within the firearms community, like so many other American success stories, it had very humble beginnings. Founded by Jeff and Kristi Hoffman and based in the beautiful Black Hills region of South Dakota, the company we know today first began in a metal shed crammed with people, stacks of boxes and a forest of hand-pumped loading presses. A rabbit warren.

Beginning by loading ammunition for the Rapid City Police Department, their reputation for quality soon spread. Eventually, law enforcement and military contracts would truly fuel the business, leading to huge opportunities. Additionally, the company would develop a line of commercial ammo catering to civilian shooters who demand the best. And it’s clear they take their work seriously.

“Every cartridge we load may have to protect a life,” they told me. That perspective has helped Jeff and Kristi Hoffman grow their company, which supplies U.S. armed forces as well as a demanding civilian market. My reporting on Black Hills goes back 15 years. Most recently, as they prepared for the 2025 SHOT Show, Jeff and Kristi granted me an update.

I would like to thank Mr. and Mrs. Hoffman for taking the time to do this Q&A session with The Armory Life.

The Armory Life (TAL): How did Black Hills Ammunition come to be?

Jeff Hoffman (JH): During the mid-1970s, I was a police officer in Rapid City, South Dakota, handloading for myself and friends on the force. A colleague invited me to join him in a commercial ammo-making venture. But Kristi and I had little money and no credit. My father stepped in to co-sign a loan and put his tractor-trailer rig up as collateral. That was in 1982. I was 23.

TAL: What was this venture? Did it prosper?

JH: The company, Black Hills Shooters Supply, did help us learn business management and the challenges of private enterprise. It also sharpened our focus on the future. After six years, we decided to start our own business.

Kristi Hoffman (KH): It was a big step, because after that first loan, we pledged we’d never be late with a payment, and we would absolutely refuse to fail.

TAL: I recall my first visit to Black Hills Ammunition. Stacks of boxes. People pumping presses … .

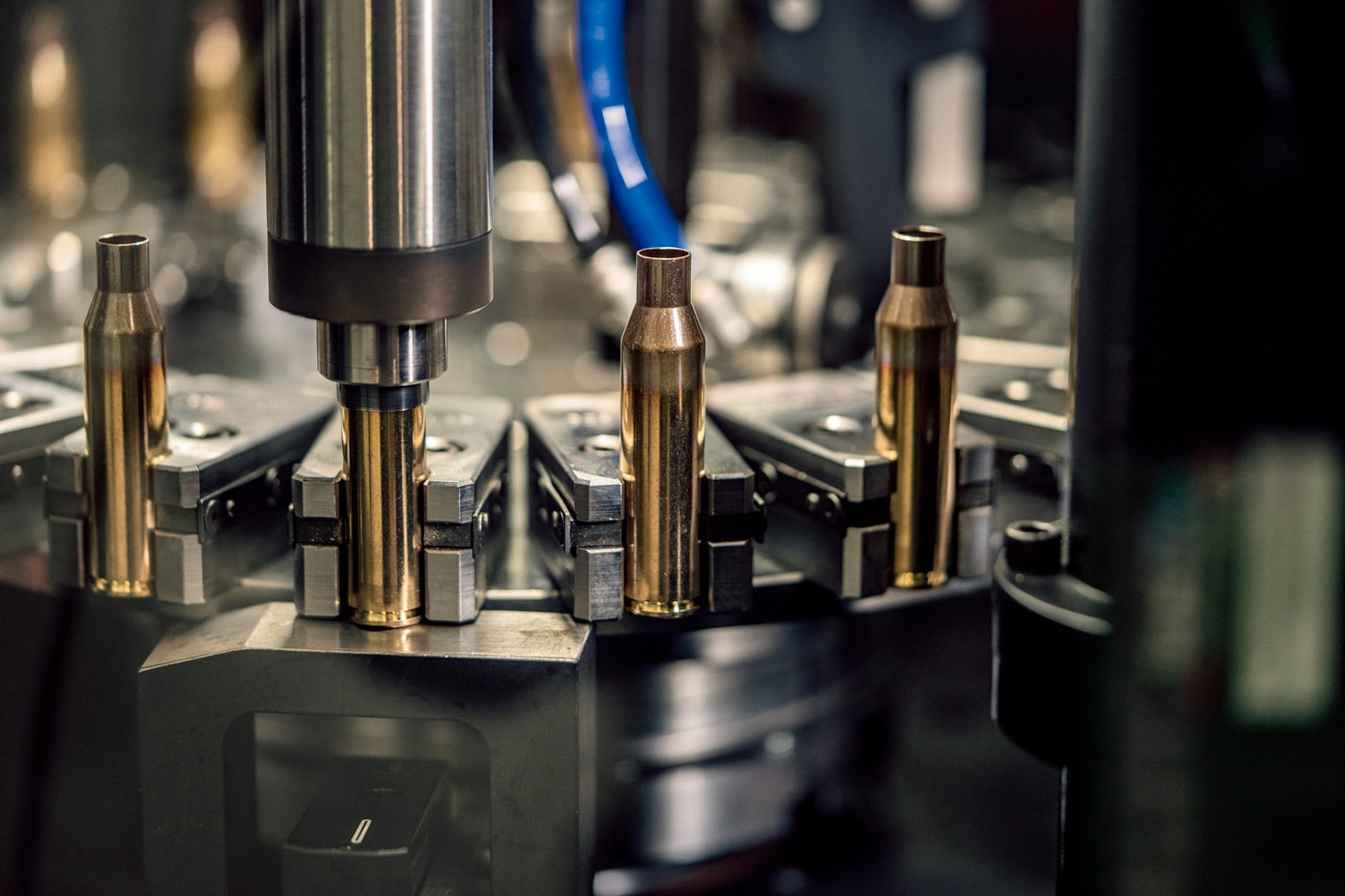

JH: It was a crowded shop! We loaded every cartridge by hand, using fired cases. We were constantly shuffling cartons of components and elbowing each other for space. We stored the ammo in a shipping container out back. But from the start, we planned to mechanize and to use only new cases.

TAL: How did you chase that dream?

JH: In 1989, Black Hills almost failed as it was competing with companies producing their own components, and with others cutting prices in desperate bids to stay in business. We maintained our focus on top-quality cartridges and explored underserved corners of the market.

One of those was the growing sport of Cowboy Action shooting. In 1994 we introduced smokeless, lead-bullet loads for vintage revolvers and lever rifles bored for the likes of the .25-20, .44-40, .38-55 and .45-70.

TAL: Still, growing in such a competitive business must have been hard.

JH: We prayed. A lot. In 1996, we got a phone call from a senior U.S. military officer inviting us to bid on an ammunition contract for the Army Marksmanship Unit. He said he’d help with the process. It was all new to us, but an exciting prospect. A 5.56 NATO load we developed with Sierra bullets met the high bar for accuracy, and our bid got us the contract.

That ammo drew attention from the Marines and Navy. Three years later, we were shipping match loads to all our armed forces. The Navy also asked for a sniper round. The accuracy spec for that was essentially 2”, 10-shot groups at 300 yards! We had worked hard to upgrade our test protocols. After many trials, we got a qualifying load with 77-gr. MatchKings.

TAL: Did success in military circles help you expand commercial product lines and grow sales?

JH: Yes. In 2002, we began offering hunting and match loads for rifles in new cases with a range of bullets. That line now comprises 53 loads for 15 popular game cartridges — .22-250 to .338 Lapua. All feature new brass and the best bullets, powders and primers the industry can supply. We have racks of test barrels for all manner of cartridges and rifling configurations.

TAL: When did you outgrow the original Black Hills facility?

KH: Very soon after our first government contract! To ensure on-time delivery of large quantities of service ammunition, we had to find a bigger facility and install new machines. In 2007, we bought a creamery on the other side of Rapid City. It had been perfectly maintained. We reconfigured the interior — 65,000 square feet — and later added 13,200 of warehousing.

TAL: How much did that new facility spur Black Hills’ growth?

JH: It was a pivotal step. Fulfilling our Navy contract for 50 million rounds of 77-gr. 5.56 ammunition in 2012 didn’t keep us from adding a 69-gr. 5.56 MatchKing load, or pairing 125-gr. bullets with .300 Blackout to duplicate light-bullet loads in the 7.62x39mm. By then, we were supplying varminters with 36-gr. Barnes Varmint Grenades at 4,250 fps in the .22-250.

TAL: What developments since have made you especially proud?

JH: In 2016, Black Hills introduced the Honey Badger bullet, named for its relentless penetration. It doesn’t expand, but rather powers through car doors, glass and other hard materials. Mid-level pistol loads give us channels as long as 18” in gelatin. Made of solid copper, with nose cuts that impart radial shock, Honey Badgers are lightweight for the bore and can be sent fast.

Our 100-gr. 9mm and .38 Special loads, and a 135-gr. offering in .45 ACP, clock 1,200 fps. A 127-gr. Honey Badger leaves a .357 Magnum revolver at over 1,350; our .44 Magnum load gets 1,700 from 160-gr. bullets. In fact, one of our 9mm Honey Badger loads has been adopted by the Navy.

TAL: Do you still sell remanufactured .223, 9mm and .45 ACP ammunition, or reload fired brass?

JH: No. Now all our ammo is made with virgin components. Black Hills assembles ammunition. It does not make components. We choose the best of those from our industry partners. They’re specialists, and very good at what they do.

S&S Bullet Company makes lead bullets for our Cowboy Action loads. We share the patent for Honey Badger bullets with Lehigh Defense, which produces them for us. Lehigh also makes our Dual Performance bullets.

TAL: How many people does Black Hills Ammunition employ? And how do you find and keep the best people?

KH: There are 65 on our current payroll. Notably, quality-control staff outnumber our production crew. Many of our staff came to us by word of mouth — personal reference. Over the past 43 years, we’ve used other ways to recruit personnel, from newspapers to staffing agencies.

To no one’s surprise, we find that if we treat talented people properly, it is pretty easy to keep them. Of course, both of us work to that end.

TAL: What is Black Hills’ annual production?

JH: Our automated loading machines chug out pallets of cartridges every hour. Tens of millions annually.

TAL: What is your most successful product?

JH: By volume, we’ve sold more .223, 5.56 and .308 target ammunition than any other. We currently list 15 loads in .223, with a 62-gr. Barnes TSX for deer hunters where they can legally use centerfire .22s.

The MK 262 load we delivered to the Navy in the late 1990s is still produced exclusively at Black Hills. We added a commercial version, not proofed in military rifles, a couple of years ago. From a 14½” barrel, it plows huge cavities in gelatin 1” to 9” past entry, penetrating 12”.

TAL: How much of Black Hills’ business comes from military contracts?

JH: These days, our production is heavily weighted to military ammo for the U.S. and its allies. We’ve developed 35 special loads for these armed forces. While commercial sales to dealers generate less revenue, hunting, match, self-defense and Cowboy Action cartridges are still an important part of our current and planned production. They account for more business than do sales to law enforcement groups.

Incidentally, while LE contracts usually go to the lowest bid, sniper ammunition does not. Snipers demand one-hole accuracy. I spent 28 of my 38 law enforcement years as a designated sniper. While the average shot distance in sniper engagements is only about 50 yards, the exposed target can be very small, and the window of opportunity brief. Innocent lives may hinge on the precise placement of the first bullet.

TAL: To what do you attribute Black Hills’ success?

KH: I think hard work and commitment have had the most impact on our continued success. We always strive to work more efficiently and ship product of the very best quality. Our customers have come to expect excellent ammunition and service, and we work hard to keep their loyalty.

Some might be surprised to learn Black Hills is still a small business. Our production — in cartridge count but also in variety, quality and value — is the direct result of the efforts and dedication of all our employees. Everyone here cares about the company and its customers. That’s what makes Black Hills successful.

TAL: What brings you the most satisfaction in making ammunition?

JH: I once got a call from the U.S. Navy where the officer told me our ammo was saving lives. What could bring more satisfaction than to know we’re making ammunition that might save the lives of our warfighters and people who depend on them?

TAL: Jeff and Kristi, you both manage Black Hills. What benefits does the partnership bring? How about challenges?

JH: We’re both committed to the business, both keen to solve problems that might impede its success or growth. Pleasing customers is our common focus. We guarantee satisfaction. If customers aren’t happy, we aren’t!

Of course, in any shared effort, there are rocks in the path. Clear and frequent communication helps us avoid them.

KH: Jeff and I have separate, distinct responsibilities. Jeff handles the production end of the business, and I focus on the administrative part. We don’t step on each other’s toes. Customers don’t get different responses from us, because we’re as ready to refer questions as to answer them.

TAL: Kristi, how do you bring up a family and manage this business?

Kristi: Doing both jobs was a challenge when our kids were young, and we had to juggle imperatives at work with home life and school activities. We were lucky to have great employees to help us run the business. Now our children are self-sufficient.

While our family is still very close, scheduling conflicts have diminished. Grandchildren have another layer of caretakers to help! But I’m blessed with the flexibility to make time for the youngsters.

A capable and willing staff lets me work nights and weekends to catch up on what I might have missed while watching a Christmas concert or a basketball game. It’s one benefit of running our own business!

TAL: What are your biggest challenges at Black Hills?

JH: Keeping up with daily chores and preventing and fixing problems on the production floor while ensuring uninterrupted flow of components, courting new customers and signing contracts months into the future. It’s a consuming job with a host of details that can’t be ignored. Penalties for poor judgment can be severe. You can’t shift responsibility or pretend you didn’t get the memo.

KH: For me, it’s ensuring there’s enough work for all employees during slow times and that we can fulfill all our obligations when there’s a flood of orders.

Growth matters, too. The success, even the survival of a company, can hinge on its progress. If the market offers a chance to grow, you must take it. Otherwise, the competition will. Success in business can come down to snatching opportunities.

TAL: What are your long-term goals, for yourself, your family and Black Hills?

JH and KH: We both want to continue making ammunition to serve our customers, our industry and our country. Keeping Black Hills prosperous is a challenge, but also a privilege, and immensely satisfying.

Eventually, though, we’d like to take a vacation. We’ve not had more than a week off in one stretch since 1993! But neither of us commits much too time to dreaming of vacations. We truly love what we do!

TAL: Thank you so very much for taking the time to talk with us and giving us this fascinating behind-the-scenes look at the story behind Black Hills Ammunition. It has been a pleasure.

RH and KH: It was our pleasure as well.

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in and discuss this article and much more!

Join the Discussion

Featured in this article

Read the full article here